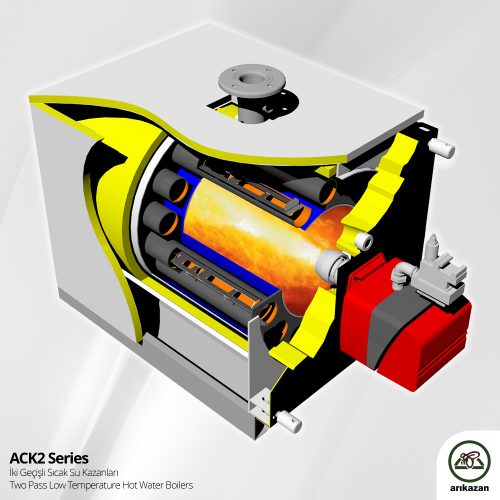

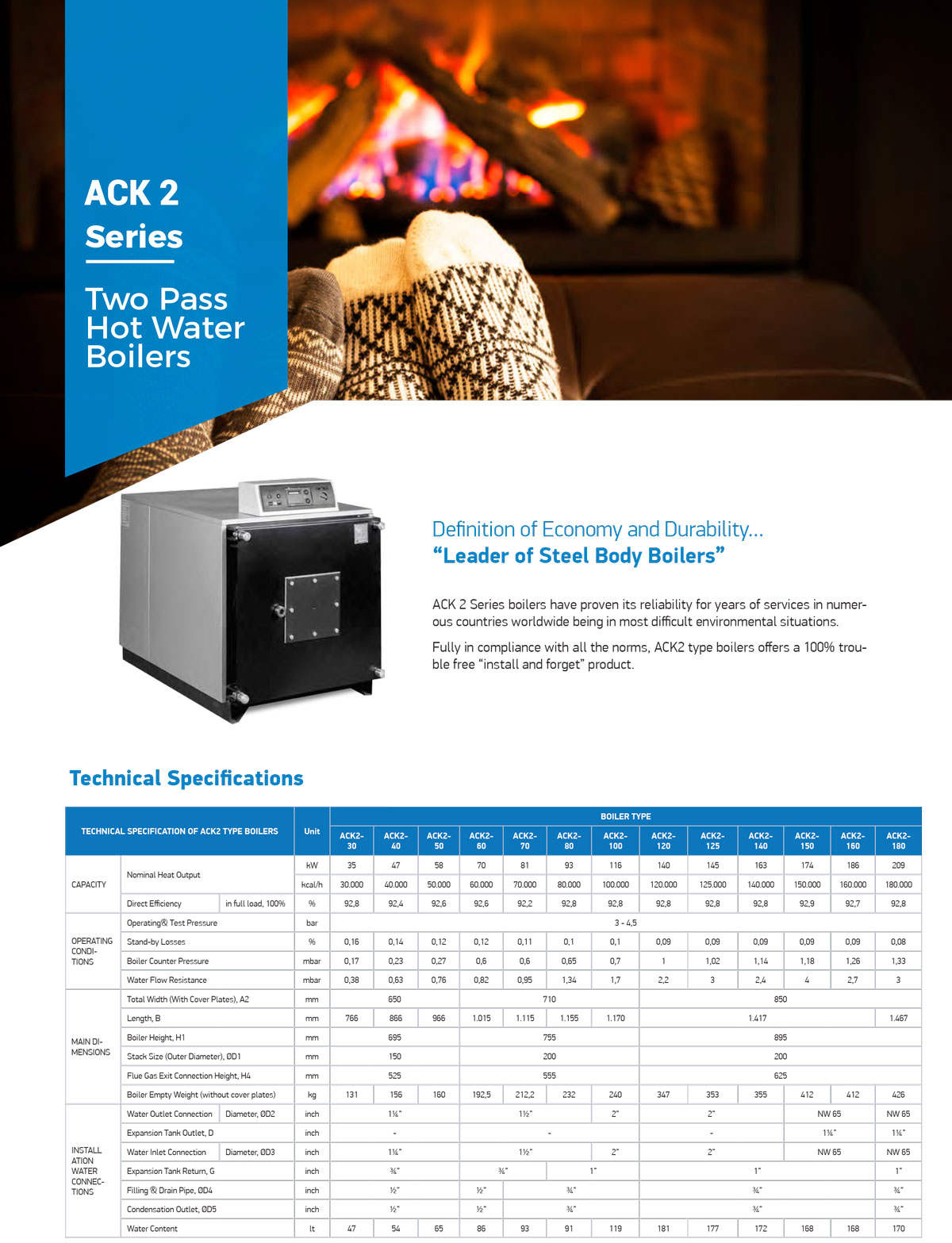

ACK 2 Series

Two Pass Low Temperature Hot Water Boilers

Defining Reliability and Economy: The ACK2 Series

The ACK2 series epitomizes reliability and economy, establishing itself as a trusted choice for heating solutions worldwide. With a proven track record of years of service across numerous countries, the ACK2 series has continuously evolved through years of experience and field feedback, culminating in a 100% trouble-free, “install and forget” type of product.

One of the key features of the ACK2 series is its exceptional flexibility, allowing for seamless integration with both natural gas and oil burners. Regardless of the fuel type, the ACK2 series delivers unrivaled endurance, even in the harshest working environments.

Experience peace of mind with the ACK2 series—an embodiment of reliability, economy, and enduring performance, setting new standards in the industry of gas and oil fired boilers.

About Product

PRODUCT OF ADVANCED TECHNOLOGY:

Entire production, designs and materials comply with both European and National standards.

All production is handled by latest automation techniques as all materials are cut in full CNC Plasma cutting, and fire tubes, inlet outlets are punched in CNC Punching, all weldings are performed by NC welding robots to ensure leak free product.

HIGH EFFICIENCY:

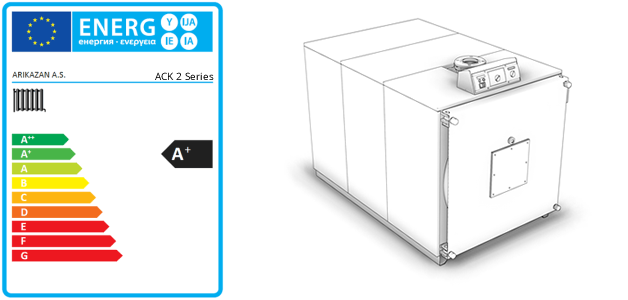

High norm efficiency up to% 96 (CE verified) is obtained by use of large volume combustion chamber design maximizing heat transfer surfaces. Boiler gas & water side resistances, stand by time losses are minimized and European Nox norms are achieved by CAD design processes. -MORE-

MORE - BOILER EFFICIENCY:

Flue gas temperatures has been lowered to 175 – 185 C and 95% - 96% efficiency values are attained based on DIN 4207-8 norms, providing 3% more efficiency values, when compared to EN minimum efficiency norms which allows boiler to be qualified to bear international “**-two stars energy & performance” mark.

ENVIRONMENT FRIENDLY:

No hazardous materials for environment and used in our products nor in the production processes. We ensure our environment friendly policy not only controlling our processes but also for all our suppliers by demanding them to provide necessary certificates for their products. -MORE-

MORE - NOX & CO EMISSIONS:

Large combustion chamber allows complete burning of fuel along with low flame temperatures by use of optimal heat transfer surfaces. Burner compatibility in compliance with the norms, allows hazardous gasses such as carbon monoxide, nitrogen oxide to be kept below European norms. These values are all tested in EU confirmed labs and have obtained the right to be used in all environment sensitive European countries.

LONG SERVICE LIFE:

All Certified materials, balanced and reliable design on heat expansion points, certified automated welding methods, Design & production in European norms and approved automatic resource management methods offers longer service times then ever.

BURNER COMPATIBILITY:

Thanks to our versatile design, special high pressure and long ballast burners are not required. High efficiency is attained with stable, smooth and silent combustion by all burners that comply with EN676 and EN267.

AESTHETIC APPEARANCE:

Boiler cover jackets are protected against corrosion and external factors by 3 features:

- Hot dipped Galvanized (GALVATITE®) steel material.

- Protective double layer special organic undercoat plating.

- Special organic paint in front, with top layer protective and aesthetic plating. (COLORCOAT®)

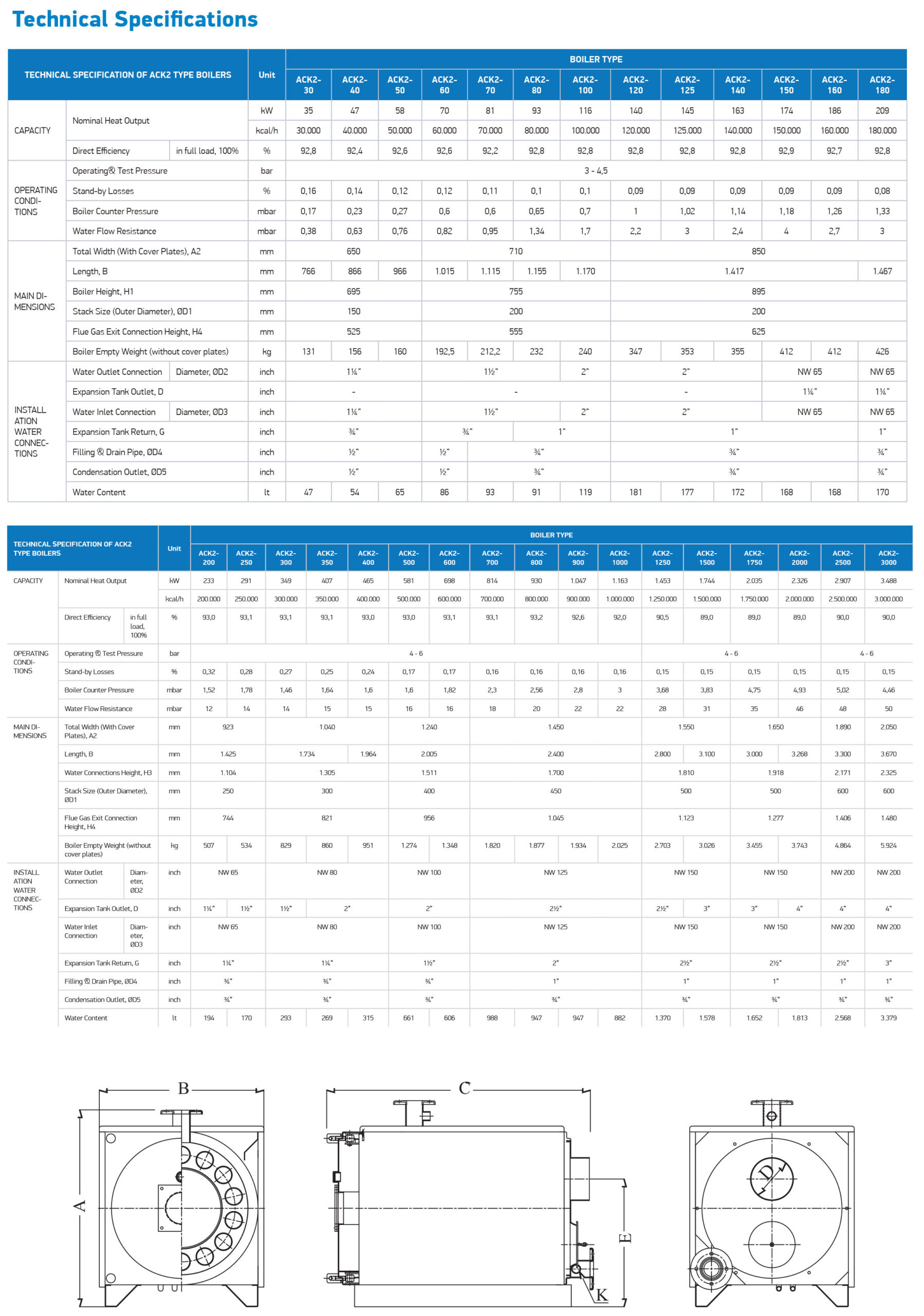

Technical Specifications

Product Brochure

Click to download.

Canada

Canada